INEOS Infinia

Find out how difficult-to-recycle PET plastic waste could be used over and over and over again

What's so special about our Infinia technology?

INEOS Infinia – enabling circularity for un-recyclable PET plastic waste

Infinia Technology, enables currently unrecyclable PET plastic waste – such as black food trays and coloured bottles –to be diverted from landfill or incineration and instead transformed back into new, virgin-quality feedstocks.

The new feedstocks are interchangeable with those made from traditional hydrocarbon sources and can be used to make new PET packaging that may be recycled again and again.

Infinia is complementary to mechanical recycling, dealing with PET waste that is currently difficult or impossible to process using mechanical methods.

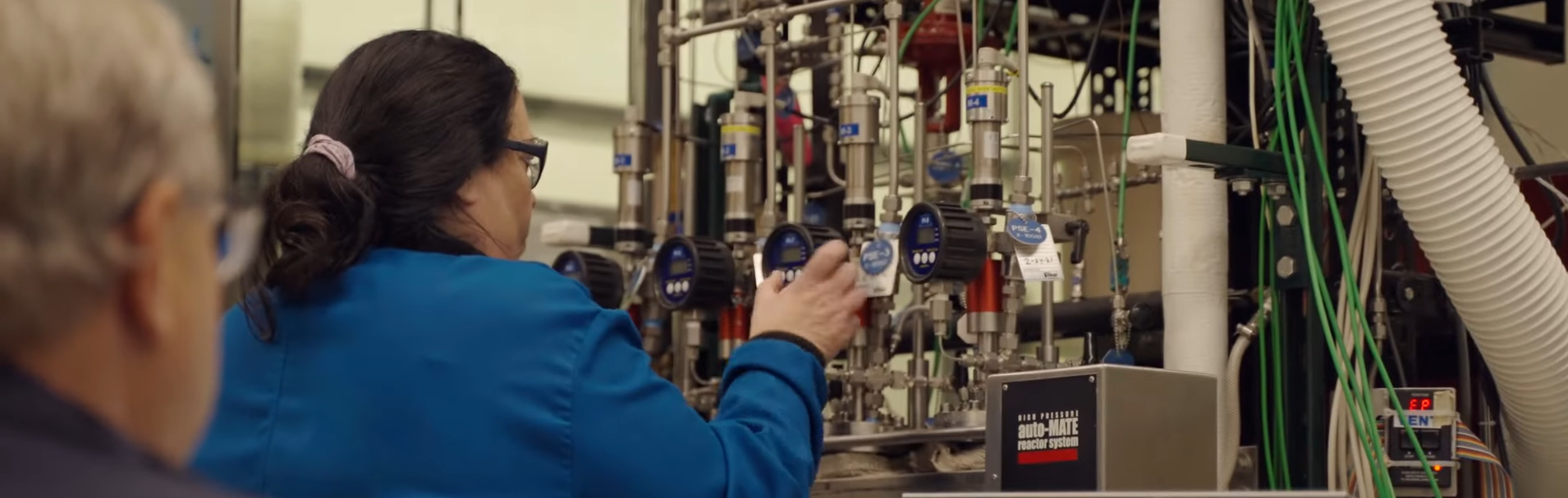

A new pilot plant, located in Naperville, Illinois, is expected to prove the technology on a continuous basis. It is an important step towards developing full-scale commercial plants using this technology around the world. If deployed at scale in a number of facilities the technology has the potential to prevent billions of PET bottles and trays from ending up in landfill or incineration every year.[¹]

[1] Production of recycled PTA, from various facilities, at the scale of one existing PTA plant (more than 1 million tonnes), would require feedstock totalling many millions of tonnes of opaque and difficult-to-recycle PET packaging. Based on the average weight (from 10 to 30 grammes) of specific packaging types suitable for this technology, this feedstock would equate to billions of packaging items.