INEOS INCH ISSUE 18

Also

-

A 4X4 BUILT ON PURPOSE – an uncompromising off-roader that works for the world

-

We Made History Today

October 12, 2019 - Eliud Kipchoge becomes the first man to run a marathon in under 2 hours

-

Rule Britannia

Scroll Down

-

A 4X4 BUILT ON PURPOSE – an...

As INEOS gears up to build its no frills Grenadier in the UK, engineers put it through its paces

INEOS’ new, no frills 4x4 will be built in Britain – and it will be named after the London pub where the idea was born. The long-awaited announcement followed months of soul searching for the best possible location.

“We looked long and hard at possible manufacturing locations across the world,” said INEOS Chairman and Founder Sir Jim Ratcliffe. But Bridgend in South Wales beat the lot.

“The decision to build in the UK is a significant expression of confidence in British manufacturing, which has always been at the heart of what INEOS stands for,” said Jim.

As INCH went to press, work was well underway to build its manufacturing and assembly plant in the small Welsh market town.

Economy and Transport Minister Ken Skates said the Welsh Government had worked closely with INEOS to make it happen.

“This is great news for Wales,” he said. “And Bridgend has a long history of skilled manufacturing expertise.”

The new manufacturing plant is being built on a 14-acre plot of land close to Ford Bridgend’s 40-year-old plant, which is due to close in 2020, with the loss of 1,700 jobs.

Production of The Grenadier – named after a poll of INEOS Automotive’s online followers – is due to start in 2021, and is expected to create up to 500 jobs.

Key parts for the 4x4, including the body and chassis, will be built at a second, sub-assembly factory in Estarreja, Portugal, before being brought to Bridgend for assembly.

BMW will supply the engines, and another German company, MBTech, a former subsidiary of Mercedes Benz, has been awarded the engineering contract.

The Grenadier has been described as the spiritual successor to the Land Rover Defender, which ceased production in January 2016.

“That left a serious hole in the marketplace and we are going to plug that gap,” said Jim.

The Grenadier will be rugged, capable, durable and functional – and easy to repair in a field.

“It will be a working tool to get the job done,” said Dirk Heilmann, CEO INEOS Automotive. “No frills. No fuss.

Pushing to the extreme

The Grenadier is being designed to withstand the toughest conditions in the world. For the past 12 months, the development team has been running a chassis and suspension “mule” to test the durability of these critical components. And so far it is faring well.

And the team have been trying their hardest to find The Grenadier’s weak spots – for months. “Believe me, we’re looking for them,” said Alex. In fact, they have been pushing The Grenadier, INEOS’ no frills 4 x 4, to the extreme.

It has already covered several thousand kilometres on and off-road.

Most of the tests have been carried out at Austria’s Graz Magna proving grounds – a favoured place to test military trucks and tanks.

“It was the ideal environment for us because we were able to push the vehicle beyond expectations,” he said.

The prototype has also been put through its paces at Germany’s Boxberg testing ground, which is used by all major European car manufacturers.

But its most recent test took it to the 4,593ft summit of Austria’s Schoeckl Mountain, which is seen as the place where 4x4s can let themselves go as they tackle the punishing climb over sharp limestone rocks to the top.

“Historically it has been used by Daimler for the G-class,” said Alex. “But The Grenadier handled it extremely well.”

Discover more at: www.ineosgrenadier.com

4 minutes read Issue 18 -

We Made History Today

Second to none

JUST 26 seconds had stood between Eliud Kipchoge and history. But in the end, the greatest marathon runner of all time didn’t need them. In a seemingly effortless performance, he ran 26.2 miles in 1:59:40 – beating his own personal best by 45 seconds – to become the first man on earth to comfortably run a marathon in under two hours.

As he crossed the finish line in Vienna, he declared: “We all made history today.”

The 34-year-old Kenyan was referring to the INEOS-backed supporting cast who had worked round-the-clock, and behind the scenes, to help make it happen.

The team of scientists, researchers, his coach, his manager, his nutritionist, his physiotherapist, the driver of the electric car who had controlled the speed of the race – and the 41, world-class pacemakers whose job had been to shield Eliud from any wind.

“Today is Eliud’s day but everyone can come out to celebrate this moment,” said two-time Olympian Lopez Lomo, who was one of the pacemakers.” We are all part of history. We all did this together as a running community.”

But there were others too.

The 120,000 spectators, who had lined the route to cheer him on, included INEOS’ Chairman and Founder Sir Jim Ratcliffe, a keen sportsman who has run more than 30 marathons himself.

“For that last half a kilometre, it didn’t look like Eliud’s feet were touching the ground,” said Jim. “He looked so calm and tranquil.”

Together that winning team had ensured that no stone was left unturned to help Eliud achieve his goal.

His performance on the day encapsulated Eliud the man – calm, consistent, patient and totally unflappable.

And there to see him race, for the first time, was his wife Grace and their three children.

She had telephoned him the night before his marathon attempt with a few words of advice.

“I told him he just needed to relax,” she said.

Man and machines in perfect harmony

The Car

An electric car controlled the pace of the race to ensure Eliud ran at the same speed for the entire 26.2 miles. But during testing, the team discovered that cruise control systems on cars are not 100% accurate. In short, they realised if the pace car ran 0.1kph too slow over two hours, Eliud would finish the race in 2:00:34.3. The RML Group, a high performance automotive engineering company in the UK, were hired to ensure that didn’t happen.

Lasers

The car was also fitted with lasers that shone a pattern on the road to help the pacemakers hold their formation – and a digital LED board so the runners could keep track of the time.

Transponder

The runners and the car carried a transponder chip, which was read by each of the one kilometre markers, providing accurate feedback on split times and speeds.

The crowd

Eliud Kipchoge wanted a big crowd because the bigger the crowds, the better he performs. About 120,000 spectators lined the entire, tree-lined route to cheer on Eliud.

Man on bike

Valentijn Trouw, Eliud’s manager, handed Eliud Kipchoge a bottle of 215 millilitres of energy drink Maurten every 5km.

The second car

To ensure nothing was left to chance, a second car – equipped with the same software as the first – was on standby should the team encounter a problem.

Pacemakers

Eliud’s pacemakers were primarily there to shield him – as much as possible – from the wind. They ran in a never-seen-before formation, which created a little pocket of air around him. Every few kilometres, a new team of pacemakers took over because no other athlete in the world can run at the same pace as Eliud without resting.

Vienna

Vienna was chosen to host INEOS’ 1:59 Challenge because it was within a three-hour time difference of Eliud’s training camp in Kenya, it had a long, flat, sheltered, straight course, where spectators could watch the race, and the weather was likely to be good.

The world was watching

INEOS 1:59 - The challenge in numbers

120,000 spectators lined the route on the streets of Vienna

500+ million people watched the challenge through global broadcasters & online via YouTube

12,500 online press articles

2.9 BILLION cumulative readership

17 BILLION impressions across all social channels

No Human Is Limited - The campaign in numbers

850,000 global followers - #NoHumanIsLimited became the third top trending topic on twitter on the day of the INEOS 1:59 Challenge (behind two other INEOS 1:59 related hashtags)

13 BILLION - The campaign reached 13 billion on twitter alone with 215,000 #NoHumanIsLimited posts on twitter and 30,000 posts on Instagram

8 of the Best - 8 ambassadors each with their own story of breaking through barriers to achieve the remarkable:

- Chris Froome

- Patrick Vieira

- Sir Ben Ainslie

- Hermann Maier

- Abdi Nageeye

- Elaine Wyllie

- Robby Ketchell

- Dame Tanni Grey-Thompson

#No Human Is Limited

ELIUD Kipchoge didn’t just want to make history on the streets of Vienna. In running a marathon in under two hours, he wanted to show the world something else. That no human is limited. As he crossed the finish line in 1:59:40, he said: “I expect more people all over the world to run under two hours after today.”

For years experts had insisted that the human body was simply not capable of running 26.2 miles in under two hours. But they had said that before. About the four-minute mile. In the 1940s, that was not only considered impossible, but also dangerous. But on May 4, 1954, Roger Bannister believed he could do it – just as Eliud believed he could become the first man of earth to run a sub, two-hour marathon on October 12, 2019.

Sixty-five years separated these two historic events but both men prepared to meet their destiny by visualising victory. Sadly Roger Bannister wasn’t alive to witness Eliud’s incredible achievement in Austria. He died of Parkinson’s disease in March 2018, aged 88. And Eliud, at just 34, wasn’t alive when 25-year-old Roger Bannister famously ran a mile in 3:59.4 at the Iffley Road track in Oxford. But they shared a common bond. Neither man believed in setting limits.

Eliud – and the team who helped to stage the INEOS 1:59 Challenge – now hope that others will be inspired to push boundaries and challenge themselves in a way they may never have dared.

“Any human being can go beyond their limits,” said Eliud. “Any human being can go beyond their thoughts. But self-belief is crucial.”

Roger Bannister’s record stood for just 46 days. And over the past 50 years, more than 1,000 athletes have run a mile in under four minutes. “The runners of the past had been held back by a mindset that said they could not surpass the four-minute mile,” said Bill Taylor, author of Simply Brilliant: How Great Organisations Do Ordinary Things in Extraordinary Ways.

Eliud’s legacy may be one for the history books, but he is now focused on running a campaign to inspire the world. His No Human Is Limited campaign has already won an army of high-profile supporters from the world of sport and business.

Among them is four-time Tour de France winner Chris Froome. “To see Eliud break the two-hour record proved that limits can be defied and actually that limits should never be set in sport,” he said.

8 minutes read Issue 18 -

Rule Britannia

The British challenger for The America’s Cup looks to the past as it endeavours to shape the future

ELEANOR Roosevelt said the future belonged to those who believed in the beauty of their dreams.

At INEOS TEAM UK’s base in Portsmouth, those dreams – sketched out on paper about 18 months ago – have just become a reality.

INEOS’ involvement in The America’s Cup challenge was always going to produce something spectacular. And it has. In the shape of a futuristic racing yacht that can ‘fly’. “This is unlike anything ever seen on the water before,” said Chief Designer Nick Holroyd.

The boat, with its torpedo-style hull, has been christened Britannia in memory of the Royal Family’s famous racing yacht which notched up an enviable 231 wins during its lifetime. Back then, Britannia, built for King Edward in 1893, really did rule the waves. The INEOS boat – the team’s first – was officially unveiled in October.

Sir Ben Ainslie, who hopes to lead the first-ever British team to victory in The America’s Cup 168-year history, spoke before INEOS Founder Sir Jim Ratcliffe and his daughter Julia named her Britannia.

“I am biased of course but I think Britannia is a wonderful acknowledgement of our maritime history,” said Ben.

The 75ft AC75 is now being put through its paces on the waters of the Solent, the strait that separates the Isle of Wight from mainland England. It then moves to Italy to make best use of the winter wind and weather off the coast of Sardinia. How it performs at sea will determine what changes are made to the second boat, which will be launched in February 2020.

“This is a really critical period in the campaign,” said Ben. “The learnings will go into our second race boat and into the America’s Cup itself in 2021.”

Despite many attempts, no British crew has ever managed to land sailing’s most coveted trophy. “The quest to win has required a fresh approach, a new strategy and serious support from INEOS to focus entirely on the mission in hand,” said Ben.

The first opportunity the British team will get to test their design against their four main rivals will be in Cagliari, Sardinia, in April 2020, when all the yachts will compete in the first of the America’s Cup World Series races. The 2021 America’s Cup Match itself will be contested in March 2021.

Although the team has “a reasonable idea” of what to expect from its AC75, thanks to simulators which the design and sailing team use ashore, the dynamics are hard to predict.

“They are likely to present new challenges to the sailors,” said Ben.

Lessons are already being learned by the crew who will be bidding to rewrite history in 2021. Exactly what, is being kept under wraps, but the design of the INEOS Team UK’s second boat will be refined.

“We already know many things we would do differently for our second boat,” said CEO Grant Simmer.

The clock has now really started ticking for all teams, who are due to compete for the coveted America’s Cup.

Grant said Sir Ben Ainslie’s British crew wanted to launch a test boat early.

“Our first test boat T5 was really good because it gave us a programme and project to work on early in the campaign,” he said.

“It was good getting the shore team and sailing team together and getting some systems in place. We learnt from just getting out and sailing a boat in this configuration.”

Their aim now is to maximise their time on the water with their first AC75 ‘Britannia’ and study the designs of the other teams’ boats.

“Those two areas will lead to the design of our second AC75,” he said.

One boat they were not able to study performing on the water until very recently was Emirates Team New Zealand as they didn’t build a test boat, and instead launched straight into their AC75 programme.

“Since the last Cup they’ve relied a lot on their simulator - like all the other teams – but I don’t think their strategy was that risky,” said Grant.

Grant said New Zealand’s deck layout was very simple with a strong emphasis on energy production. But with potential speeds reaching above 50 knots, the competition is wide open.

“We could very easily see failures because these boats are very light and can capsize,” he said. “A major structural problem close to the cup could definitely lose it for anyone.”

AC75 Britannia

Construction hours: 50,000 +

Design hours: 90,000 +

CNC Machine hours: 45,000+

Individual parts: 25,000

Estimated top speed: 50knots /57.5mph /92.6km/h

Length: 22.76m with bowsprit (20.7m without)

Max Beam: 5m beam

Weight: 6,450 tonnes

Hull and rig construction: Carbon fibre

Rig: Double-skinned soft-wingsail

Crew: 11

Crew weight: Max 990kg

6 minutes read Issue 18 -

Proud to be British

IN the first collection of its kind, Belstaff has designed on-shore clothing for the British team.

It has drawn inspiration from the garments worn by America’s Cup teams throughout the competition’s 168-year history.

“Just wearing Belstaff makes me feel proud because it’s such an iconic British brand that’s adventurous and always pushing the boundaries,” said skipper Sir Ben Ainslie.

The 23-piece collection, which merges iconic Belstaff pieces with high-performance materials designed to last, will go on sale to the public from April next year.

INEOS bought Belstaff in October 2017.

1 minute read Issue 18 -

Belstaff

The Road Less Travelled

BELSTAFF is drawn to risk-takers, those who thrive on adventure and are not afraid to veer off the beaten path. So too is INEOS.

That’s why the two are a perfect fit. INEOS, which bought the iconic British clothing brand in 2017, and Belstaff understand each other.

Now members of the public have been given an opportunity to listen to an original podcast series from Belstaff, exploring the lives of five different talented souls, who have taken unfamiliar roads in life by challenging both who they were ‘meant to be’ and the wider status quo.

Their stories are shared in the podcast series, entitled The Road Less Travelled, which has been described by GQ Magazine as the perfect antidote to a miserable morning commute.

In the first series, host Reggie Yates – no stranger to hard work and going his own way – interviews actors Stanley Tucci (The Devil Wears Prada), Raleigh Ritchie (Game of Thrones), Naomie Harris (Moonlight), Andrew Scott (Fleabag) and Emma Mackey (Sex Education).

Hosted by Reggie Yates

EPISODE ONE - STANLEY TUCCI

In this episode, actor, writer and director Stanley Tucci discusses his creative path from working-class New York, to a shy radio-voice on Frasier, before playing an Oscar-nominated role in the critically acclaimed Spotlight.

Stanley’s life, the characters he has portrayed and the stories he has told, have become reflections of his own remarkable journey - he regards this as a paramount part of his creative process.

EPISODE TWO - RALEIGH RITCHIE

In this episode we meet actor and musician Jacob Anderson AKA Raleigh Ritchie. Raleigh left his family in Bristol to live in a hostel in London - where he auditioned all day, recorded his next album at night and eventually landed the monumental role of ‘Grey Worm’ in Game of Thrones propelling his career into the Hollywood stratosphere.

Raleigh’s personal struggles with identity, new-found fame and his mixed heritage give him a unique view on the world - one that fuels his desire to be authentic - in his performances, music and life.

EPISODE THREE - NAOMIE HARRIS

In this episode we meet Naomie Harris, multi-award winning actress and the star of Oscar winning film, Moonlight. Naomie discusses her community drama school in North London, being an outlier at Cambridge University, and how stepping out of her culture and standing apart - eventually led to her cinematic success.

Naomie’s devotion to playing powerful female characters, from Eve Moneypenny to Winnie Mandela, are re-defining the scripts of history and giving humanity, complexity and personality to icons of popular culture.

EPISODE FOUR - ANDREW SCOTT

In this episode we meet Andrew Scott, who discusses coming out in Catholic Ireland, forgiving the church and how his latest role in the highly acclaimed series Fleabag will potentially alter Britain’s perception of priests today.

Andrew’s deep love for human nature, whether it’s playfulness, insecurities or a desire for success - have been truly influential on his life as an actor, as a friend and as Britain’s most infamous characters in Spectre and Sherlock.

EPISODE FIVE - EMMA MACKEY

In this episode we meet Emma Mackey, actress and star of Netflix series Sex Education. Emma discusses growing up in rural France, trying to fit in at school, and what it’s really like to shoot a sex scene.

Emma’s own character, and the character that she’s risen to fame playing, all embody a sense of individuality. A feature she feels is desired by all of modern society.

WWW.BELSTAFF.CO.UK/PODCAST-AW19.HTML

Location Location Location

Belstaff’s appetite for change shows no signs of flagging as it moves its flagship London store to a better site

BELSTAFF’S adventure into the High Street continues. Since INEOS took over the iconic British clothing brand in October 2017, it has reopened and relocated stores. The latest decision saw a new flagship store open in London’s Regent Street, which attracts more than 50 million visitors a year to its eclectic mix of iconic British and international brands.

For the past six years the company’s flagship store had been based in New Bond Street, but with a new vision for store design and a community building focus, it was time for a move.

The new shop is close to Soho, one of London’s most vibrant neighbourhoods which will be reflected in the store.

“The space can be transformed from a retail environment into a community hub very easily because all fixtures are on castors,” said CEO Helen Wright. And Belstaff intends to do that.

It wants to host an ongoing series of curated events with guest hosts along with special screenings, panel discussions and podcast recordings.

And key figures from the Soho community were involved in the official opening event, curating the food, music and entertainment.

As with many of Belstaff’s revamped stores, there’s plenty of room for customers to enjoy a coffee or G&T while their old jackets are given a new lease of life at the in-house waxing station.

Classes will also be run to show customers how to care for their Belstaff waxed cotton and leather jackets.

Those classes will be filmed and shared on Belstaff channels.

“They will also highlight the importance of sustainably-designed products that are built for life,” said Helen.

For almost 100 years, Belstaff has kitted out some of the most daring people the world has ever seen, including aviator Amy Johnson, adventurer TE Lawrence and revolutionary Che Guevara. “The jackets they wore are still made by Belstaff today,” said Helen.These are exciting times for Belstaff.

In March, INEOS reopened its Spitalfields store in London.

In May it relocated the Munich store to Residenzstrasse, the vibrant heart of the German city.

And in July Glasgow’s Belstaff branch was moved from Princes Square to a much bigger site in Ingram Street.

But there is one constant: the customer must always come first.

7 minutes read Issue 18 -

Innovators not imitators

Sustainability through innovation

INEOS are investing in hundreds of active projects on carbon, hydrogen, heat & power, renewables, resources and waste

Renewable raw materials, made from sustainable wood-based waste are being used to replace traditional raw materials originating from oil and gas based products. The resulting polymer products from INEOS contribute to measurable Greenhouse Gas (GHG) savings.

Innovation is not just about having ideas. It’s about making ideas happen...

THOMAS Edison – arguably the greatest inventor in history – had some sound advice for those wanting to follow in his footsteps. "The value of an idea," he said, "lies in the using of it." As a company, INEOS excels when it comes to making great things happen. Every day.

Pete Williams, INEOS’ Group Technology Director, is in no doubt about that.

“INEOS continues to improve its sustainability, and its products help to improve the sustainability of many things we all take for granted in our day to day lives,” he said. “We want to be delivering valuable products to customers not just today but also in 10, 20, 30 years and beyond. So as a growing world sets its target to move towards net zero carbon emissions, INEOS will adapt and move with it to meet its needs, to overcome its challenges and seize new opportunities.”

To do this, innovation is key. At INEOS Innovation and sustainability are inextricably linked.

INEOS products already makes a powerful contribution to a more sustainable world by making possible a wide range of products for various industries, including automotive, healthcare, medicine, aerospace, renewable technologies, construction, electronics, electrical and household goods, and packaging.

Independent reports calculate that if polymers were to be replaced to the maximum level by the next best alternatives, greenhouse gas emissions would more than double.

“Looking forward, we are innovating to make an even stronger contribution,” said Pete.

Every day the company is focused on improving the efficiency of its sites and reducing emissions.

More efficiently-run plants are not only better for the environment, but they can create savings which can then be reinvested elsewhere.

The polymers INEOS produces contain mainly carbon. “We see our job as looking after the carbon,” said Pete. “We see it as using it as efficiently as possible, and recovering and re-using it as much as possible.”

INEOS has already launched a range of new polymers containing recycled plastics.

It is also looking at how to use bio-sourced carbon – carbon from natural sources rather than oil and gas – and has launched new bio-products, such as Biovyn. “All these reduce emissions further,” said Pete.

But to be truly sustainable INEOS must make sufficient profit so it can re-invest in new state-of-the-art manufacturing techniques and equipment.

“The analogy is that we need to be able to replace the old, inefficient car of 30 years ago with a new, much more efficient version,” said Pete. And that’s what INEOS is now doing.

In January this year INEOS announced it planned to spend €3 billion on a new cracker and propane dehydrogenation complex in Antwerp.

The investment, described by Chairman Sir Jim Ratcliffe as the largest of its kind in Europe for more than a generation, will enable a step change reduction in emissions associated with the manufacture of olefins, the key intermediate for a broad range of products used in automotive, construction, transportation and medical applications.

In summary, INEOS intends to remain sustainable and meet the challenges of the changing environment through innovation.

And it doesn’t matter where the ideas come from. “Good ideas can come from anywhere,” said Pete. “Our staff, our customers, our supplies.”

Those ideas can be quickly shared through efficiently-run networks, such as the Carbon and Energy Network.

Greet Van Eetvelde, INEOS’ head of energy and innovation policy, said INEOS is involved in hundreds of active projects on carbon, hydrogen, heat & power, renewables, resources and waste.

“Many of them are innovation projects linked to universities and other organisations as we seek to harness expertise and work with cross-sector businesses to optimise the significant benefits from our industry and beyond,” she said.

Those in-the-know are already aware of what the chemical industry has done to make cars and planes lighter and more fuel efficient.

They understand that without the chemical industry, there would be no wind turbines and solar panels.

They recognise the important role the chemical industry has played in bringing water to some of the poorest parts of the world.

“We know what we have done, what we are doing and what we can do to create a low carbon economy,” said Pete. “The difficulty, as always, is changing the public’s perception of what we do.”

Innovations in plastic recycling

INEOS is at the heart of many, new innovative products thanks to its forward-thinking and dynamic approach.

INOVYN fuels new, greener generation of PVC

SINCE its invention more than 100 years ago, PVC has been made predominantly from fossil fuels. Some countries, including Brazil, have used sugar instead as a starting material but that’s also not been without controversy.

“Europe is especially sensitive to using land for anything other than growing crops to feed people,” said Dr Jason Leadbitter, Sustainability & Corporate Social Responsibility Manager at INOVYN.

But times are changing – and INOVYN is at the heart of one monumental change.

Instead of purely gas and oil, the INEOS-owned company has starting using biomass to make its latest generation of PVC. The beauty of this, as a raw material, is that it is not only renewable but it also does not compete with the food chain.

“No one else has done this yet,” said Filipe Constant, Business Director INOVYN. “It’s a world first, and it also delivers a greenhouse gas saving of more than 90% compared to conventionally-produced PVC.”

The new product is BIOVYN™ – and interest is now flooding in from all corners of the globe, including Australia, America and Turkey.

“We have had lots of requests and from lots of different sectors, including the car industry, medical suppliers and window and pipe manufacturers,” said Inna Jeschke, marketing manager for General Purpose Vinyls at INOVYN.

Biomass PVC delivers a greenhouse gas saving of more than 90% compared to conventionally-produced PVC

To make it happen several key pieces of the jigsaw first needed to come together.

INEOS O&P in Köln, Germany, has been instrumental in securing the biomass – the raw material – to ensure it could satisfactorily be converted to bio-ethylene.

And converting this bio-ethylene to produce BIOVYN has only been made possible through a robust and transparent standard developed by the globally-respected Roundtable for Sustainable Biomaterials (RSB). Once the jigsaw was complete, INOVYN needed customers.

“You can produce something but you need customers who are prepared to buy it because it is more expensive,” said Inna.

Tarkett, a flooring company with offices all over the world, liked what it saw.

“We believe in doing good together,” said President Fabrice Barthélemy. “And we are convinced there is an urgency to shift models to preserve the world's finite natural resources.”

Tarkett plans to use BIOVYN™ to manufacture a new flooring collection due to be marketed in Europe next year.

“Thankfully countries in Scandinavia are really driving the renewable agenda,” said Inna.

The biomass-derived raw material is shipped by barge to INEOS O&P’s plant at Köln where it is turned into bio-ethylene in its existing cracker. That is then piped directly to INOVYN’s plant at Rheinberg in Germany.

“We cannot say it is bio-based because the bio-ethylene will still be mixed with fossil-ethylene,” said Jason. “But that is where the RSB standard plays a fundamental role by ensuring that the bio-ethylene is attributed to the BIOVYN product.”

He described it as a major step forward in INOVYN’s journey towards sustainability.

“It clearly demonstrates our commitment to developing innovative solutions that address society’s needs,” he said.

The Roundtable on Sustainable Biomaterials, whose global mission is to support best practice for sustainable bio-material production, is full of praise for INOVYN.

“This product is a true leader in the emerging circular bio-economy,” said executive director Rolf Hogan.

Recycled plastic gets a fresh start

PLASTIC waste, once destined for landfill or burning, is now being recycled into a range of high quality plastics. INEOS has spent a lot of money researching ways to use these recycled plastics with their customers.

“We don’t like to make a big fuss until we know we have something to show,” said David Kirkwood, Polymer Business Manager. “But using 50% or more recycled plastic in our products is a big achievement.”

INEOS hopes its long-term agreements with recycling companies, including Viridor, will show the public that plastic waste is a valuable resource that should be brought back to life, not used once and thrown away. And together they have hatched a plan to do that.

The household rubbish is collected, sorted and cleaned before being turned back into recycled plastic pellets, which INEOS then processes with a better quality plastic at its own sites to make a product that is as good as the original.

“INEOS has applied extensive material science and process expertise to design and produce this completely new range,” said CEO Rob Ingram. INEOS customers have been hugely positive about the Recycl-IN product range.

In the past, brand owners or consumers were not keen on recycled plastic because it lost some of its quality during the recycling process and the end product was just not as good. But Recycl-IN has overcome that obstacle. Recycl-IN can be used to make many household products in just the same way as normal plastics. “You would not notice the difference in a laundry detergent bottle, for example,” said David.

Using 50% or more recycled plastic in our products is a big achievement

For it to run smoothly, INEOS will need a steady supply of recycled plastic pellets and next year Viridor is opening a state-of-the-art recycling plant in Avonmouth to cope with the demand.

“The difficulty for INEOS is that we need to rely on others in the value chain for our raw materials and that starts with every one of us recycling their plastic in the first place,” said Gabriella Isidro, Business Development Manager. “Everyone in the value chain needs to work together on this. We are just one of the cogs in this wheel.”

Like any other process, what comes out at the end is dependent on what you put in at the start. “Therefore if you start with a lot of different colours then the end product will be grey,” said Gabriella.

As industry cannot 100% control, or be sure, how these products have been used, the European Union says they cannot come into contact with food.

Liz Rittweger, Business Director for INEOS Olefins & Polymers, said there was no point in recycling plastic, if society doesn’t use recycled products.

“This is not a PR exercise,” she said. “Recycl-IN provides excellent uses for large amounts of recycled plastics.”

Bright sparks make the grade

TWO innovative companies, with a shared vision of a circular economy, are now commercially producing high quality plastics, using up to 70% recycled content.

INEOS Styrolution and Austrian recycling company bage plastic have developed the perfect recipes for very first recycled ABS grades that are just as good as those made with fossil fuels.

“This partnership combines their recyclates and first-class sorting technology with our manufacturing expertise and innovative capabilities,” said a spokesman for INEOS Styrolution.INEOS Styrolution will be using recycled electrical and electronic waste to make the new grade, which is known as TERLURAN® ECO GP-22.

“This collaboration will also take us closer to meeting INEOS’ target to incorporate at least at least 325 kilotonnes per annum of recycled material into its products,” said Sven Riechers, Vice President, Business Management, Standard Products EMEA.

Up to 70% recycled content is now being used to produce high quality plastics

Bage plastics, which converts post-consumer plastic waste into high-value plastic granules and compounds, said both companies wanted to recover and recycle as many materials as possible.

“We both want to minimise waste and reduce our impact on the environment,” said general manager Philipp Baum.

INEOS Styrolution employs about 3,500 people and operates 20 production sites in 10 countries.

Global Thinking - Global Action

Innovation is hard at work in INEOS and is reaping all sorts of rewards

Cleaner Fuels

The North West Hydrogen Alliance is currently looking to exploit various funds set aside to decarbonise the UK. INEOS business INOVYN has been working with the British Government in an attempt to ensure that hydrogen is the path to a low carbon future. INOVYN, which has been making hydrogen as a co-product for over 100 years, is prepared to invest if local and central government and other companies get onboard to help develop the infrastructure.

Industrial Symbiosis

Final tweaks are being made to a INEOS-driven plan to share resources with different industries in Hull in the UK. By sharing resources, they will be able to cut carbon emissions by about 4,100 tonnes a year. The four-year EU-funded EPOS project looked at ways for five, energy-intensive industries – chemical, steel, cement, minerals and engineering – to improve efficiency, cut costs and reduce carbon emissions.

Partnerships

INEOS is now using 50% or more recycled plastic to produce a range of high specification polymers. To ensure it has a steady stream of plastic waste for its Recycl-IN range, it has signed long-term agreements with recycling companies, including Viridor. Together they hope to show the public that plastic waste is a valuable resource that should be brought back to life, not used once and thrown away.

Sustainable Chemistry Awards

INEOS encourages innovation from the next generation of engineers through its Sustainable Innovation Awards. Building on its Research and Innovation contacts and projects with universities INEOS has launched an Awards programme for Master theses in engineering faculties. Many of the students, who win the award, end up working for INEOS.

Biomass

INOVYN has started using biomass – in addition to purely gas and oil – to make its latest generation of PVC. No one else has done this yet. It’s a world first, and it also delivers a greenhouse gas saving of more than 90% compared to conventionally-produced PVC. The new product is BIOVYN™ – and interest is now flooding in from all corners of the globe.

Networking

INEOS’ group-wide network, CEN (Carbon & Energy Network), operates across all its businesses, supporting on-site best practices, initiating new business opportunities and fuelling innovation.

Full Steam Ahead

As part of a project known as ECLUSE, INEOS Phenol in Antwerp helped to finance a 5km pipeline to help others businesses. INEOS could already pipe steam to its own site from INDAVER/SLECO’s waste and energy plant at Doel but other chemical companies couldn’t. Now they can thanks to the pipeline, which links them all to INDAVER/SLECO. The pipeline will also reduce greenhouse gases by 100,000 tonnes a year.

Investment

INEOS’ ground-breaking decision to ship competitive US gas to Europe paved the way for further investment in new, more environmentally and economically sound infrastructure at Antwerp.

Global Thinking - Global Promises

As part of its own commitment to a new circular economy, INEOS has set itself four ambitious targets to meet by 2025

325,000 - INEOS wants to incorporate at least 325,000 tonnes of recycled material into its products

30% - Use, on average, 30% recycled content in products destined for polystyrene packaging in Europe

50% - Offer a range of polyolefin products for packaging applications in Europe containing 50% or more recycled content

100% - Ensure 100% of polymer products can be recycled

To discover more of the innovative and sustainable work INEOS are doing please visit: www.ineos.com/sustainability

14 minutes read Issue 18 -

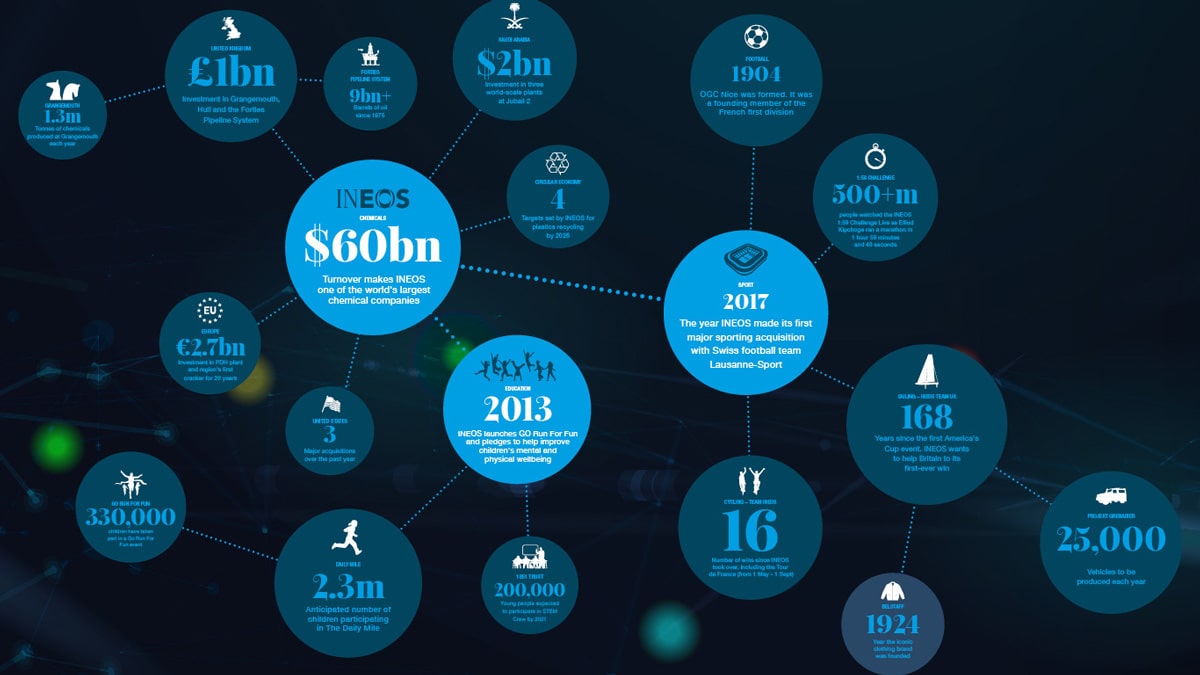

The Right Chemistry

AFTER 20 years of investment and innovation, INEOS has not only become a major manufacturer of chemicals and oil products, but a company committed to the circular economy, tackling plastic waste, applying best practice and ensuring the well-being and potential of future generations.

Through new technologies, processes and partnerships, INEOS has grown exponentially, acquiring unloved businesses, building world-scale facilities and rejuvenating existing assets.

It has made bold moves beyond its conventional markets in recent years, breaking into the automotive sector, leading major sports teams and encouraging young talent to fulfil their potential.

INEOS' conviction, commitment and strong team ethic has proven a winning formula and remains the cornerstone of its strategy moving forward.

4 minutes read Issue 18

4 minutes read Issue 18 -

Six rivers project

Iceland. Wild. Beautiful. Untouched. And home to one of the last safe havens of the Atlantic salmon.

But in recent years their numbers have been rapidly declining across the world – and it is now on the verge of becoming endangered.

Rather than give up hope, a small group of people in Iceland, where the species still thrives, have been investing their time and money in trying to reverse the decline, before it is too late.

INEOS’ Chairman and Founder Sir Jim Ratcliffe, a keen fly fisherman, is among them.

RESEARCHERS from Iceland and the UK are now pooling their expertise as part of a wider plan to help save the Atlantic salmon. The teams from Imperial College London and The Marine & Freshwater Research Institute in Iceland have been brought together by INEOS Chairman Sir Jim Ratcliffe.

Over the next four years, they will devote their time and energy to find out what threatens the salmon’s survival once they leave the safe haven of the Selá, Hofsa, Miðfjarðará and Sunnudalsá rivers in Iceland and migrate to the sea.

“The cause of their decline globally is not entirely known,” said Professor Guy Woodward, the lead academic working on the project.

INEOS-sponsored PhD student Olivia Morris, who will be analysing the new and old data alongside a PhD student from Iceland, said there were a number of possible reasons, including climate change, pollution, and the destruction of their habitats.

But she said, in Iceland, increased fish farming and pelagic fishing were more likely to blame.

“Iceland still has relatively healthy populations because many of the challenges salmon face elsewhere are not a major concern there,” said Guy. “But that means the likely causes in Iceland should be easier to identify and to model so we can predict future changes before they happen.”

Strengur Angling Club, which recently began leasing the fishing rights to the Miðfjarðará and the Sunnudalsá rivers, has been protecting the Selá and Hofsa for decades.

In 2004 the club reduced the equipment that fishermen could use and in 2012 introduced catch and release. Most recently they have banned the use of large hooks on the Selá river.

Over the years salmon ladders have also been built to allow the salmon to reach new spawning grounds further up the river.

The most recent - the Miðfjarðará ladder - opened in 2017 thanks to investment from Sir Jim.

“Without him we would not have been able to do this,” said club director Gísli Ásgeirsson, who said there were plans to open two more salmon ladders.

But more needs to be done.

The latest research by Imperial College and the institute in Iceland will build on Strengur’s work and inform ongoing conservation efforts.

So far, as part of the project, botanists have been planting larches, birch and willow to enrich the soil around the rivers.

“This project is very new and hasn’t been tried before in Iceland,” said botanist Else Muller. “But when you get heathier vegetation around the rivers, then you get a healthier environment for the organisms that live in the rivers. It is all connected.”

Up to one million eggs from native fish will also be planted further upstream in five rivers. The first batch were dug into the gravel in temperatures of minus 10°C.

“By planting eggs in the river, hopefully in the next five or 10 years, we will have a healthier and stronger stock,” said Jon Magnus Siguroarson, chairman of the Hofsa River Association.

The team has also tagged 1,000 smolts (maturing salmon) to discover where they go.

Together the scientific and academic teams will be trying to understand what is causing the salmon’s decline and what they need to do to reverse it.

Guðni Guðbergsson, head of the freshwater division at the Marine & Freshwater Institute, said the INEOS-funded research project would greatly help the plight of salmon in North East Iceland.

“We have been monitoring the rivers in North East Iceland for the past 40 years and that will continue alongside this project, which will give us the opportunity to further analyse existing and new data,” he said.

One miraculous fish

What all those involved in the project share is a huge admiration for the Atlantic salmon – and the struggles it has to overcome.

These incredible fish migrate thousands of miles in their lifetime but return to the same freshwater river, where they were born, to spawn.

“Sometimes they may have spent two years maturing at sea but they use their sense of smell to find their way home,” said Professor Guy Woodward from Imperial College London.

They can not only swim fast but they can jump up to 12ft.

Jim gets involved

In collaboration with the Strengur Fishing Club, which provides the best quality fly-fishing in the world, INEOS Chairman Sir Jim Ratcliffe has initiated a string of investments to help protect the land, rivers, and salmon in North East Iceland.

Egg planting

Eggs have been planted into the gravel in rivers further upstream to help breed a healthier and stronger stock. The salmon will spend their early life in the freshwater rivers before heading out to sea. After a few years, they will return to the place, where they were born, to spawn.

Planting

Botanists have been planting larches, birch and willow to enrich the soil around the rivers. Healthier vegetation around the rivers leads to a healthier environment for the organisms that live in the rivers.

Smolts

1,000 smolts (maturing salmon) have been tagged so that scientists can track them and monitor their behaviour.

Salmon ladders

So far three salmon ladders have been built to allow the salmon to reach new spawning grounds further up the rivers. There are plans for two more.

The long-term goal for salmon fishing in Iceland

ICELANDIC rivers are world renown for their salmon fishing - and attract enthusiasts from all over the world every year.

Former US President George W Bush, who died about a year ago, was among those who fished the Selá river.

“It is impossible to describe the wonders of fishing the Selá,” he said. “It is an astoundingly beautiful river. The fish, fresh from the sea, are strong fighters and remarkably beautiful.”

But if Iceland’s salmon disappear in the same numbers as those in Norway, Scotland and Ireland, money for farmers living in remote parts of North East Iceland, where the fish currently thrive, could dry up.

For sports fishing, done respectfully – where all fish must be released carefully back into the river – brings them a good income.

INEOS Chairman Sir Jim Ratcliffe, who is an expert fly-fisherman, has been working with Strengur Angling Club, which provides the best quality fly-fishing in the world, for years.

Together they hope to see more money flowing into the club’s coffers from world-class salmon fishing, so that Strengur can expand its own business – and fund more conservation work.

8 minutes read Issue 18 -

OGC’s new keeper

ONE of the oldest football clubs in French history is now in INEOS’ hands. INEOS Football has acquired OGC Nice, one of the founding members of the French football league.

“It has got all the attributes we were looking for in a good football club,” said CEO Bob Ratcliffe. “Good players. A good squad. Real enthusiasm. And if we apply the INEOS values we will get to the right place.”

With four league titles to their name, the club also has a rich history. But their last cup triumph was in 1997.

INEOS will be looking to instil some of their trademark grit and determination to make them European contenders once again.

“We have looked at a lot of clubs in the manner we look at businesses in INEOS - for value and potential - and Nice fulfils that criteria,” said INEOS Chairman Sir Jim Ratcliffe.

Solange Claude, President of CDS 1947, Nice Supporters Club, said the city strongly identified with its football club and had high hopes following INEOS’ takeover.

“We are hopeful for this season,” she said. “Even though we didn’t start very well, we know with INEOS coming, we will overcome any obstacles and win, little by little.”

Jean-Pierre Rivere, President of OGC Nice, said everyone was feeling positive.

“What is happening right now at the stadium is something unbelievable,” said assistant coach Frederic Gioria. “I never thought that one day INEOS would own our club.”

Success is something familiar to Patrick Viera, who has been head coach since last season.

He has played for Juventus, Inter Milan, Manchester City, Arsenal.

“INEOS coming to our football club is a massive step forward, not just for us but for the French league as well,” he said. “The INEOS brand is so well known. It will make us more ambitious. We have people who are experienced and have been successful in business.”

OGC, which was founded in 1904, currently plays in Ligue 1, the top tier of French football. Its stadium, the state-of-the-art Allianz Riviera, can accommodate 35,000 fans. Earlier this year it hosted matches during the FIFA Women’s World Cup.

The decision to buy OGC Nice follows the acquisition of Lausanne Sports Football Club in November 2017.

“We made some mistakes at Lausanne, but we are fast learners,” said Jim. “Those mistakes have been rectified and we are already seeing the benefits.”

He said clubs needed to be successful off the pitch, as well as on it. “OGC Nice will be no different,” he said. “We have a plan in place and we will follow it.”

Patrick Vieira

Head Coach at OGC Nice and considered one of the best players of his generation. He has achieved major honours for both club and country.

Arsenal:

- 3 x Premier League.

- 3 x FA Cup.

- 3x FA Community Shield.

Inter Milan:

- 4 x Siere A.

- 2 x Supercoppa Italiana.

Manchester City:

- 1 x FA Cup.

France:

- 1 x FIFA World Cup.

- 1 x UEFA European Championship

- 1 x FIFA Confederations Cup.

OGC Nice Remaing fixtures: 2019-2020

LYON

V

NICE

Nov, Sat 23

NICE

V

ANGERS

Nov, Sat 30

ST ETIENNE

V

NICE

Dec, Wed 4

NICE

V

METZ

Dec, Sat 7

BREST

V

NICE

Dec, Sat 14

NICE

V

TOULOUSE

Dec, Sat 21

ANGERS

V

NICE

Jan, Sat 11

NICE

V

RENNES

Jan, Sat 25

NICE

V

LYON

Feb, Sat 1

REIMS

V

NICE

Feb, Wed 5

NICE

V

NÎMES

Feb, Sat 8

TOULOUSE

V

NICE

Feb, Sat 15

NICE

V

BREST

Feb, Sat 22

BORDEAUX

V

NICE

Feb, Sat 29

NICE

V

MONACO

Mar, Sat 7

PSG

V

NICE

Mar, Sat 14

NICE

V

MONTPELLIER

Mar, Sat 21

DIJON

V

NICE

Apr, Sat 5

NICE

V

STRASBOURG

Apr, Sat 11

LILLE

V

NICE

Apr, Sat 18

MARSEILLE

V

NICE

Apr, Sun 26

NICE

V

NANTES

May, Sat 2

METZ

V

NICE

May, Sat 9

NICE

V

ST ETIENNE

May, Sat 16

AMIENS

V

NICE

May, Sat 23

FC Lausanne-Sport Remaing fixtures: 2019-2020

LAUSANNE SPORT

V

WIL

Nov, FRI 22

KRIENS

V

LAUSANNE SPORT

Nov, Sat 30

LAUSANNE SPORT

V

VADUZ

Dec, SUN 8

GRASSHOPPER

V

LAUSANNE SPORT

Dec, FRI 13

FC SCHAFFHAUSEN

V

LAUSANNE SPORT

JAN, THUR 23

LAUSANNE SPORT

V

KRIENS

FEB, Sat 1

CHIASSO

V

LAUSANNE SPORT

FEB, Sat 8

LAUSANNE SPORT

V

AARAU

FEB, Sat 15

WINTERTHUR

V

LAUSANNE SPORT

Feb, Sat 22

WIL

V

LAUSANNE SPORT

Feb, SAT 29

LAUSANNE SPORT

V

BASEL

MAR, MON 2

LAUSANNE SPORT

V

VADUZ

MAR, SAT 7

GRASSHOPPER

V

LAUSANNE SPORT

MAR, Sat 14

LAUSANNE SPORT

V

FC SLO

MAR, Sat 21

AARAU

V

LAUSANNE SPORT

APR, Sat 4

LAUSANNE SPORT

V

CHIASSO

Mar, SUN 12

LAUSANNE SPORT

V

FC SCHAFFHAUSEN

Mar, Sat 18

KRIENS

V

LAUSANNE SPORT

Apr, Sat 25

LAUSANNE SPORT

V

GRASSHOPPER

MAY, Sat 2

VADUZ

V

LAUSANNE SPORT

MAY, Sat 9

LAUSANNE SPORT

V

WINTERTHUR

MAY, TUE 12

FC SLO

V

LAUSANNE SPORT

May, FRI 15

LAUSANNE SPORT

V

WIL

May, TUE 19

5 minutes read Issue 18 -

Air Quality Monitoring- INEOS Offices

A growing body of scientific evidence points to the negative human health impacts of air pollution, both outdoors and indoors. As engineers and manufacturers, we are aware of the importance of mitigating emissions from our sites; however recent studies have shown the necessity and efficiency of ensuring healthy air quality for employees in our office environments too.

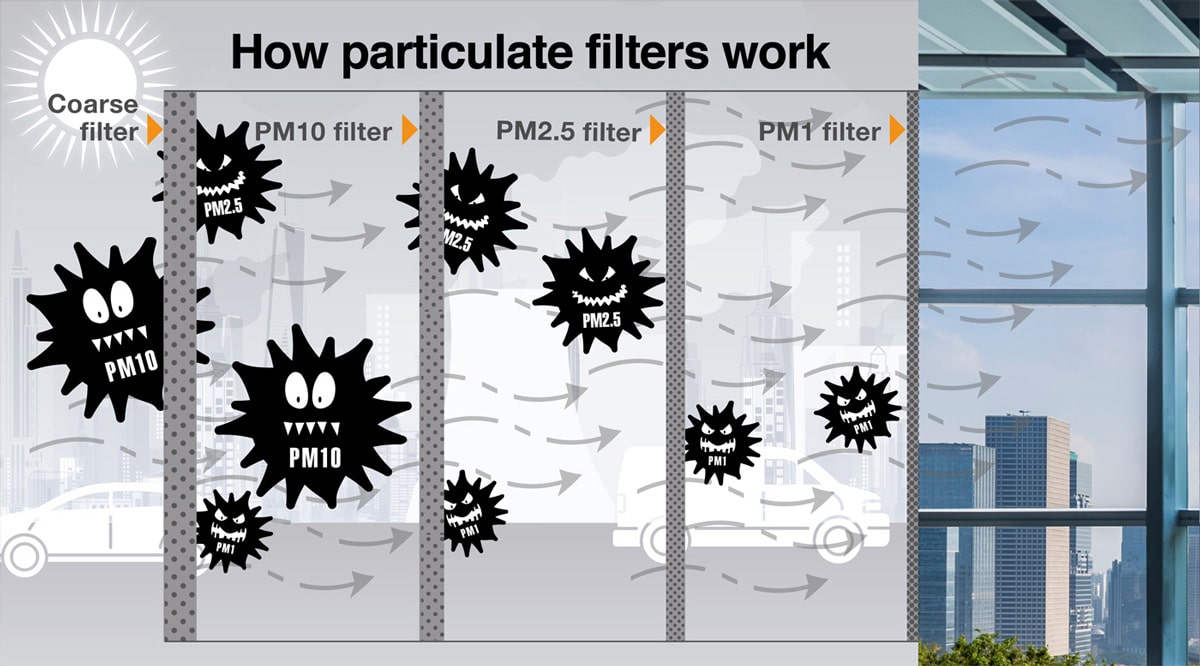

There are two forms of pollutant. Gaseous such as Volatile Organic Compounds, carbon monoxide, sulphur oxides, ozone, methane, carbon monoxide/dioxide and nitrogen oxides (including NO2). The second is from particulates- fine particles suspended in the air that are for example emitted from cars.

With research ongoing, legal authorities and international bodies such as the EU 2008 EU Air Quality Directive and the World Health Organisation (WHO) have set guidelines and recommendations for healthy limits of these pollutants in the air we breathe. These are still being refined as the body of research into harmful impacts of air pollution grows.

POLLUTED AIR IS BAD FOR HUMAN HEALTH

- Numerous studies show a direct causal relationship between air pollution (especially particulate matter of 2.5 micrograms or below) and cardiovascular disease, respiratory disease, and cancers.

- In the WHO European Region alone, exposure to particulate matter (PM) decreases the life expectancy of every person by an average of almost 1 year, mostly due to increased risk of cardiovascular and respiratory diseases, and lung cancer [1].

- Numerous studies show a link between air pollution and several other non-communicable diseases including kidney failure and septicemia [2], as well as depression and common mental health issues [3].

- Air pollutants of varying sizes (those of less than 1 microgram being most pernicious) have been found in the lungs, circulatory system and major organs such as the heart and brain, and are known to be linked to inflammation causing several other health problems [4].

MANAGING INDOOR AIR

In 2018, when INEOS Chairman Sir Jim Ratcliffe first raised the issue of monitoring office air in London as a trial, INEOS Group Operations Director Simon Laker approached the solution from an engineering background. They were aware that working in a congested and polluted capital city such as London was bound to mean higher levels of pollutants would make their way into Hans Crescent air system and potentially impact the hundreds of employees that work there. Jim wanted a state of the art solution to the air quality issue, this meant using the best and leading edge technology available.

Simon engaged the National Physics Laboratory to conduct the air quality analysis and Dr. Melanie Williams as project consultant. To ensure the data gathered was thorough and accurate, monitors were set up on the pedestrian area outside the Hans Crescent office, on the roof 24m above ground where the office air intake is drawn, and inside the office on the third floor. Data was also collected from the various monitors around the city of London required by EU regulations.

A number of pollutants were monitored: nitrous oxides, sulphur dioxide, ozone, carbon dioxide, volatile organic compounds and particulates in the two regulated sizes 2.5 micrometers (PM2.5) and 10 micrometers (PM10). In addition, analysis was deduced on even smaller particles at 1 micrometer (PM1). While the smallest particulates aren’t formally regulated by the EU, this was done, as growing research shows that the smaller the particulates, the greater their potential damage to human health [5].

It is known that pollutant levels across London are higher on many days than the EU recommended limits [6], and the INEOS monitoring confirmed this- with peak readings on some days reaching several multiples of the recommended maximum pollutant volume. The study also showed, as suspected, that levels of some pollutants were unfavourably high in the Hans Crescent internal office air system, regularly fluctuating in line with outside levels.

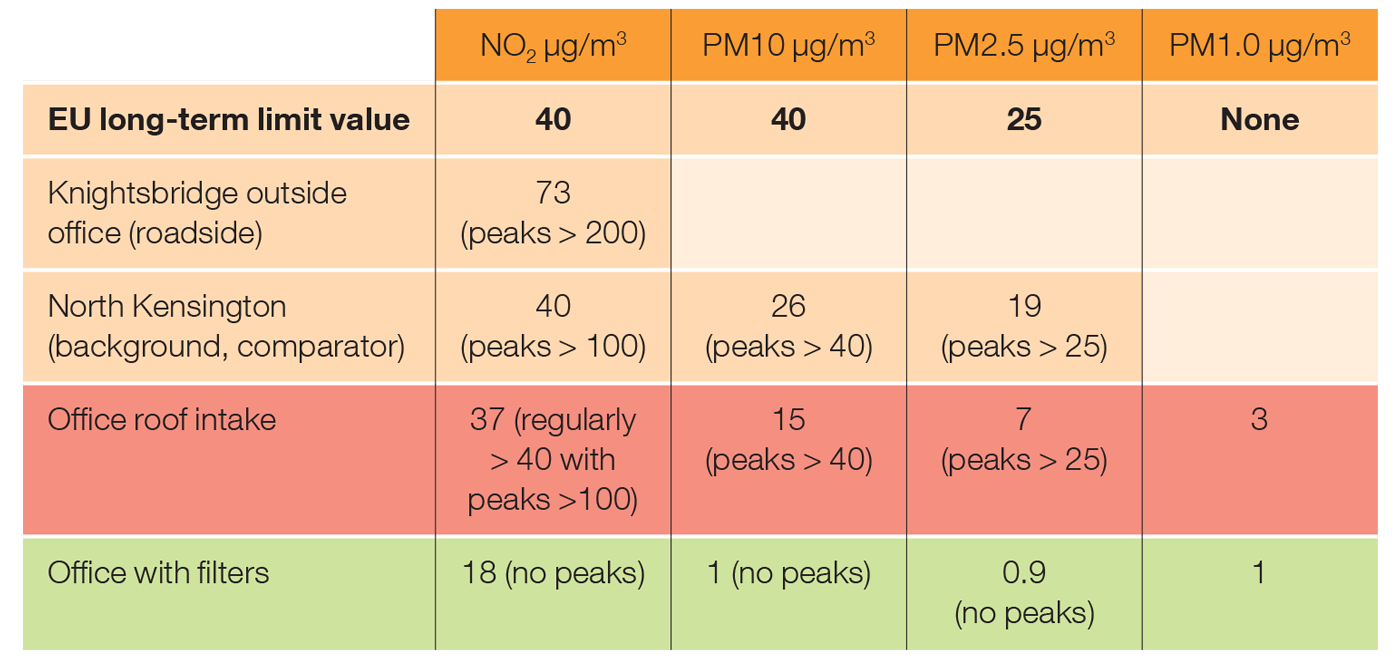

After several months of careful monitoring and analysis, it was determined that the prominent pollutants to be addressed inside the office were nitrogen dioxide (NO2), and particulates, usually generated by vehicles. Simon Laker points out that although the EU limits set a helpful baseline, the growing body of research is continually reviewing these limits downwards as more data becomes available. “We should see these as helpful markers but not definitive levels of 'safe' operation,” he says.

While the long term emission limit of NO2 is recommended by the EU to be no more than 40 micrograms (μg)per m3, with the short term limits being no more than 200μg/m3 in a single hour, in Knightsbridge outside the Hans Crescent office both these limits were regularly breached. The inside of Hans Crescent did not see these breaches but levels were still thought to be too high. Interestingly, levels improved during the night and at weekends when the air conditioning is turned off to save power: further proof of the poor air quality being pulled inside the building.

The table below summarises the key findings of the analysis:

Engineering and technology specialist AECOM, known for their world class expertise in environmental technology and design solutions, were engaged to help develop the solution for the Hans Crescent air quality issue. Working with Simon and Melanie, AECOM determined that filters of two different technologies were required- an EPM1 particle filter which removes PM10 (with 98% efficiency), PM2.5 (92% efficiency) and PM1 (80% efficiency) particles from internal circulation, and an activated carbon filter. These were added to the existing air conditioning system.

Post installation analysis showed a significant improvement in both NO2 and Particulate levels (see table above). In addition, the carbon filters reduced other lower level pollutants such as sulphur oxides and ozone.

The internal monitoring work also showed that levels of CO2 (emitted by people breathing) were higher than expected in an office environment, with regular internal levels sitting at 1000-1200 parts per million (ppm) and peaks of 1400ppm. With ideal office levels sitting at 450-1000ppm, and 1000ppm commonly seen as the watershed between quality air and complaints of drowsiness, the air turnover rate was optimized to bring levels back below 1000ppm. The positive effects of this adjustment on employee concentration and decision-making are likely to be significant, according to a recent study by the Harvard T.H. Chan School of Public Health’s Center for Health and the Global Environment [7].

With success of the air quality improvement project in Hans Crescent evident, the same changes have now been rolled out to the London sister office at Anchor House and the Swiss office in Rolle with similar positive results. A request has been made by INEOS Capital for all INEOS businesses to analyse and improve the air quality across their offices. “This work is at the cutting edge of office air quality improvement”, says Dr. Melanie Williams, and should make a significant impact on staff health and wellbeing.”

Simon considers the success of this project as a ‘bridge to clean air’. ‘’Whilst we all work to improve emissions and air quality around the world, the system we have developed and installed is ensuring that our people work in a safe and healthy environment’’.

As Jim points out, monitoring is not expensive, and where pollutant levels are high, the issues can be easily addressed with modest cost. “The welfare of our staff is hugely important to INEOS and we want to tackle the issue of air pollution, which is particularly serious in big cities”, he says. “It’s great news that our London staff can now breathe the cleanest air in the area and we are committed to making sure staff in other locations can enjoy the same benefit”.

LINK REFERENCES

- http://www.euro.who.int/en/health-topics/environment-and-health/air-quality/data-and-statistics

- https://www.bmj.com/content/367/bmj.l6258

- https://ehp.niehs.nih.gov/doi/10.1289/isesisee.2018.O02.04.31

- https://www.ncbi.nlm.nih.gov/pubmed/29519450

- https://www.thelancet.com/pdfs/journals/lanplh/PIIS2542-5196(17)30095-5.pdf

- https://www.london.gov.uk/press-releases/mayoral/two-million-londoners-live-with-illegal-toxic-air

- https://ehp.niehs.nih.gov/doi/10.1289/ehp.1510037

5 minutes read Issue 18 -

Tour de France challenge

More than 1,300 INEOS staff from its sites around the world cycled 625,387km – and raised €104,000 for a host of charities.

Their combined efforts in the company’s Tour de France Challenge equated to cycling around the world more than 15 times.

In recognition of their efforts, INEOS donated €2,000 to the local charity chosen by each of the 52 teams.

Each team was challenged to complete each stage of the world famous Tour de France race – and once again they did, squeezing in their mileage before, during or after work.

- 625,387 km Covered

- 15 x around the globe

- 1300+ people in 52 teams

- €2000 donated per team

2 minutes read Issue 18 -

Stay Safe

EVERY year hundreds of people are lured into the ‘death zone’ on Mount Everest. A handful will be prepared to die. Others will willingly lose fingers and toes to frostbite if it means they have conquered the world’s highest mountain.

“That may be their measure of success,” said Rhys Jones, who stood on the 29,035ft summit of Mount Everest on his 20th birthday. “But it’s not mine.”

Rhys today runs a company that specialises in guiding people to some of the most inhospitable places on earth. He is prepared to take risks. But only calculated ones.

And as someone who has faced unimaginable dangers, he regularly briefs companies on the importance of safety, risks and teamwork.

“There are many parallels between what happens in a company, like INEOS, and on a mountain,” he said. “But they work in a hazardous place all the time. I am only at risk in the mountains.”

Rhys, now 33, was recently invited to address INEOS O&P USA’ annual safety training event at the Chocolate Bayou site in Texas.

“When we are planning the event, we encourage everyone to think creatively about our safety messages,” said Michael Brocato, environmental engineer. “By adopting a fresh approach, we hope to inspire and motivate our employees to be safe. It doesn’t matter whether you work on an INEOS site or are standing on the summit of Everest, safety is safety.”

During his talk to the US team, Rhys explored attitudes to risk and how safety must always be the top priority.

“A successful mountaineering expedition, in my view, is always one where no one is injured,” he said. But he said, for that to work, everyone on the team had to share that vision. “As a team, you need to define your measure of success,” he said. “And mine, like INEOS’, is zero injuries.”

INEOS staff were told how he had recently guided an Everest expedition.

“Our aim was to get as high as we could without getting frostbite or injured,” he said. “We were prepared to turn back if necessary and half of the team did.”

A second expedition team, who were also planning to climb Everest that day, though, had a different view. Among them was a surgeon, who said he was willing to lose fingers and toes to frostbite. That group all made it to the summit but two thirds of them got frostbite and one climber lost all his toes.

“Everest can make intelligent people take stupid risks,” said Rhys.

On another expedition – to Aconcagua, the highest mountain in South America – a fellow climber’s eyeballs started to freeze because he forgot to wear his goggles once the sun started rising. “It was a preventable injury but it became a big issue for him and the whole team,” said Rhys. “Yet a bystander could have helped him and told him he needed to put his goggles on.”Teamwork, he said, was critical.

At INEOS, watching out for others in the team is essential. It is known as Brother’s Keeper. Rhys, who lives in a world of ropes, crampons and ice axes, said there was also no room for complacency.

“When you first start climbing you check your harness, then check and check again,” he said. “But after you have done it 1,000 times, it’s easy to become complacent. The secret is to treat every day like your first day when it comes to safety.”

Michael said the team at INEOS O&P USA had felt inspired and empowered by Rhys’ talk.

“We often use the message that our definition of a successful project is one where there are no injuries first, then business objectives second,” he said. “Rhys was able to echo that sentiment.”

He said several members of staff were also inspired to learn that it was INEOS Chairman Sir Jim Ratcliffe who had sponsored Rhys in 2006 to help him become the youngest person in the world to climb the seven highest summits on the world’s seven continents.

Rhys Jones

An English mountaineer who was the youngest person to climb the the highest mountain on each of the world's seven continents. He reached the summit of his final mountain, Mount Everest, on his 20th birthday in 2006. He and his business partner now run Monix Adventures, which specialises in luxury adventure travel.

5 minutes read Issue 18 -

Trash-4-Treats

INEOS challenged pupils from 10 primary schools in the Western Cape to collect the most plastic, glass, cans and paper for a chance to win about €3,000.

“The idea was to turn what is perceived as a chore into a fun habit,” said Caroline Hughes, INEOS SA spokeswoman. “And also to show the children that waste has value.”

The schools, which were initially chosen to take part in the Trash 4 Treats competition, were first briefed by a local recycling company, Waste Want, which would help to weigh and collect the rubbish.

Prior to the competition, INEOS hosted a litter clean-up day at each school. Starter kits were issued to each child so he or she knew what could – and couldn’t – be recycled. Each pupil was also given four different coloured bin bags so they could sort the rubbish.

After the competition ended, the 13,094 children had collected 5328kg of waste in just seven weeks. The total included 1110 kg of plastic.

But for Caroline and the team at INEOS, the biggest benefit has been a change in mindset.

“Many of them simply didn’t know why rubbish was a problem,” said Caroline. “But the hope is that the children – having seen the financial and environmental benefits – will continue to keep their neighbourhoods tidy.”

The winning school was Mitchells Heights Primary, which amassed 1519kg of recyclable waste. “I have noticed a big difference in our learners since we started Trash 4 Treats,” said a teacher.

“They now take pride in their school grounds and berate others who litter. It has been wonderful to witness children take an active interest in caring for their environment. We have started a clean revolution at Mitchells.”

All the schools, though, plan to continue their involvement with the recycling centre, which pays for the rubbish.

Caroline said the recycled plastic was especially in demand locally. “Many of the teachers and children were amazed to discover what happens to plastic bottles that are recycled,” she said.

Next year, INEOS plans to take Trash 4 Treats and its popular mascot Trashy to more schools in South Africa.

Trashy

With a new mascot to inspire the children, things are looking up.

1519kg

The winning school was Mitchells Heights Primary, which amassed 1519kg of recyclable waste.

3.75 Black Rhinos

After the competition ended, the 13,094 children had collected 5328kg of waste in just seven weeks. The total included 1110 kg of plastic. That’s the same weight as 3.75 black rhinos!

For more details log on to: trashfortreats.webtestsite.co.za

0 minutes read Issue 18 -

Two million children

AN INITIATIVE to get children fit for life has taken a giant leap since its launch in 2012. The Daily Mile has now spread to 10,000 schools in 71 countries – and it is still growing.

“Children really love it and that’s why it works,” said Daily Mile founder Elaine Wyllie, whose passion for children’s health and wellbeing has helped to drive the global campaign.

The 10,000th school joined the movement in October, bringing the total number of children, now running or walking every day for 15 minutes, to more than two million.

Next year’s focus for The Daily Mile Foundation, which is financed by INEOS, will be to increase the number of schools participating in America.

“At the moment, we’ve got at least one school signed up in half the states, with over 100 schools signed up across the country,” said John Mayock, Director of The Daily Mile project.

Bill Russell, a member of the foundation team, is based in INEOS O&P’s Houston office, and is leading the US campaign. His aim is to find partners, willing to help implement the scheme across the country.

“One such partner already involved is the University of Washington’s Sports Institute in Seattle,” said John.

The Daily Mile Foundation is also working with its super-human ambassador Eliud Kipchoge. who made history on the streets of Vienna by running a marathon in under two hours.

The foundation hopes he will spread the word to Kenya where he lives and trains.

“It would also be wonderful if his international pacemakers, many of whom are also ambassadors for The Daily Mile, took it to their home countries,” said John.

And with all eyes expected to be focused on The America’s Cup in New Zealand in 2021 – when Britain hopes to win the trophy for the first time in the competition’s history with INEOS’ financial muscle – the foundation will be exploring ways to sign up schools in Australia and New Zealand ahead of the race.

“It is going to quite a year,” said John. “We are aiming for world domination.”

3 minutes read Issue 18 -

330,629 children. 11 countries

FOUR new countries will host GO Run For Fun events in 2020. Spain, Denmark, Sweden and Brazil will all be championing the INEOS campaign which was launched by chairman Sir Jim Ratcliffe to encourage children to be more healthy and active.

Since 2013, more than 330,629 children from 11 countries have taken part in 439 showcase events.

“We celebrate every child who takes part, whether they are first, last or somewhere in between,” said Amy Tayler, manager of the INEOS GO Run For Fun project.

She said all the events were only made possible, though, thanks to an army of volunteers who helped to stage them.

Sir Jim, who is deeply passionate about running, said it had never been more important to inspire children to exercise more and eat healthier food.

The World Health Organization said the latest figures showed 41 million children, aged 0 to 5, were classed as overweight or obese in 2016.

“That has increased from 32 million globally in 1990,” said a spokesman.

At least six new GO Run For Fun events will be staged next year in new locations close to INEOS sites.

3 minutes read Issue 18 -

Breaking the mold

INEOS celebrates innovation – wherever it springs from. Every three years INEOS-owned INOVYN seeks to reward those who strive the push the boundaries with vinyl, with businesses, architects, academics, research organisations and students from all over the world bidding for a slice of that recognition.

This year a record 93 projects from more than 19 countries were submitted for the INOVYN Awards 2019, which were held in Düsseldorf to coincide with ‘K2019’, the flagship international plastics fair, thereby bringing together a range of industry leaders.

The four, independent judges were looking for excellence in four areas – sustainability, design, process and new product. And they were not disappointed.

“The projects that won this year stood out as real exemplars of innovation with vinyl,” said Leanne Taylor, INOVYN Awards judge.

AGPU, Bilcare Research and Perlen Packaging won gold in the sustainability section for their project to recycle pharmaceutical packaging.

Coperion emerged as a winner for finding a process to significantly reduce dust during the cutting of PVC pellets.

The Instituto Brasiliero do PVC won gold for designing lightweight furniture, such as shower chairs, walkers and tables, for children with neuromotor conditions.And Eurocell earned a gold award for creating a highly-durable, cladding system for coastal properties, which can often bear the brunt of bad weather. The product is 100% recyclable and needs little maintenance.

“All these products will help to deliver significant benefits,” said Leanne.

Filipe Constant, Business Director INOVYN, said innovation was the lifeblood of the vinyl industry.

“I would like to congratulate all those who entered for continuing to push the boundaries of what is possible with vinyl,” he said. “It is such innovation that makes vinyl one of the most versatile products in modern society.”

More information can be found on the dedicated INOVYN Awards website at

4 minutes read Issue 18 -

My dream is to make this world a...

SELF-BELIEF drives Eliud Kipchoge. He says that’s where his inner strength comes from. "If you have that belief that you want to be successful, then you can talk to your mind and your mind will control you to be successful,” he says.

Eliud was just 16 when he began his journey to becoming the greatest marathon runner of all time. His coach Patrick Sang remembers him as a young boy who was hungry to learn.

“I didn’t know his name,” he said. “But he kept coming up to me and asking for training programmes.” Eliud is now a household name.

But fame and fortune have never been the motivation. He simply wants to use his status to encourage others to run.

"My dream is to make this world a running world,” he said. “A running world is a healthy world. A running world is a wealthy world. A running world is a peaceful world. A running world is a joyful world.”

In achieving the seemingly impossible by running a marathon in under two hours, he wants to show the world that no human is limited. And that with self-belief, anything is possible.

Before the INEOS 1:59 Challenge, Eliud said he hoped it would inspire at least three billion people. That’s half the world. Those closest to him may have secretly thought he was being a tad ambitious. But when the final viewing figures of his historic run in Vienna were revealed, he was on his way to achieving his goal.

Not only that but the challenge had also inspired one Kenyan woman to name her newborn baby girl, INEOS.

3 minutes read Issue 18 -

1:59 Employee Challenge

In the lead up to the INEOS 1:59 Challenge in Vienna INEOS employees took part in their own 1:59 challenge. Teams of eight would run a combined distance of at least 42 Kms (26.2 miles) a day for eight days. Here is how they performed.

2419 Marathons covered

2.5x around the globe

1405 people in 192 teams

8 days

142/192 teams completed the INEOS 1:59 Challenge

Teams that:

- covered 150km+ 92%

- covered 250km+ 89%

- covered 350km+ 86%

- covered 500km+ 63%

Top 10 Teams (by distance covered):

- Lavera Double M – 1233km

- ALTAMIRA 1 – 1128km

- Lavera Reliability Team 917km

- ALTAMIRA 5 – 913km

- Trading & Shipping 1 – 868km

- INEOS Compounds 2 – 863km

- GAS/SPEC – 860km

- Rolle One – 846km

- ALTAMIRA 8 – 811km

- Köln u5 - 794km

Winner of the Eliud Kipchoge 1:59 Challenge Inspiring Award Cindy Gutierrez - Altamira 1, Mexico

Members of the 2:50 Club

- Pieter Verhees (2:40) Antwerp

- Weston Caceres (2:45) Chocolate Bayou

- Matt Robinson (2:45) ITUK, Portsmouth

- Florian Zunino (2:48) Lavera

- Fabio Robbiati (2:50) Rolle

Elevation mini-challenge winner Sebastien Fontaine - Lavera 1.672km

CHALLENGE STATS

- Runs 6296

- Men 953

- Avg. distance 531km

- Steps 89,196,319

- Women 452

- Elevation gain 374,156m

- Energy 7,252,151,578 KCAL BURNED

3 minutes read Issue 18